Back in 1876 when James Schofield bought a plot of land and buildings at Greenhead, high in the Pennines on a windswept hill above Huddersfield, horses and carts were the order of the day and transport logistics a far distant problem.

Even in the early 1900s when Joe Benjamin Schofield lent his name to what was to become the family scrap metal and plant hire business of J.B Schofield & sons Ltd the horse still ruled, in fact the first diesel engine vehicle came 13 years after Joe’s death, YG8732 a Morris commercial was bought in 1933. By 1954, following the lean post war years, money was found to buy the first new wagon, a Perkins P6 powered Dodge 5 tonner (based on payload in those days of course). The company owner at the time was Norman Schofield and his sons Carl and George could remember their father saying that it would be the first and the last new wagon he bought.

A wide variety of vehicles, Dodges and Commers to name but a few, mostly in tipper form, were to come and go, some meeting an untimely end in accidents. However, the first ‘real’ wagon to appear was RKU535 a Foden DG six wheeler built for the army around 1945. One of many built to withstand desert conditions with multiple air and fuel filters to protect the legendary Gardner 6LW 112bhp working under the bonnet, it was coupled to a Foden gearbox that had 8 gears but with only 4 on call at any one time. The lower four were only used in exceptional circumstances, of which there were plenty. The lower ratios were engaged by moving a separate lever and only when stopped. Foden’s own axles, double drive of course, brought up the rear. The big Foden was one of hundreds built for the army and then disposed of at auction at Ruddington, Nottingham. Carl had his sights set firmly on a Foden, so when George and father went to the auctions, Carl suspecting that father Norman would be reluctant to part with his money rang L.W. Vass at Ampthill and found one himself-and for less money than the Vass buyer had been paying that day at auction. Carl seems to remember paying around £1100.

Originally built on single tyres all round, Vass had converted the Foden to twins at the rear. A later visit to Foden’s at Sandbach around 1962 saw a second steering axle added, this increased the gross weight from the original 20 to 24 tonnes. The removal of the army’s split, opening windscreen, replaced with one piece of glass either side gave the wagon a more civilian appearance. A reconditioned Gardner 6LW was included in the work. Bought to carry scrap, Schofield’s had a wooden drop side tipper body and Milshaw tipping gear fitted, a second deck of ‘greedy’ boards were fitted to give the capacity needed for the bulkier loads, it also stopped prying eyes from seeing what was on the old Foden’s back, after all loads could be a little on the heavy side, no point in attracting the attention of the Bobbies, what the eye doesn’t see!

RKU started to rack the miles up, steelworks at Skinningrove, Scunthorpe, Sheffield and Stavely being regular destinations. The 100 odd miles to the North East was a six hour journey, the 28mph top speed only achieved on downhill or long flat stretches of road. Not many of those in the Northern hills!

The cab of the Foden became second home to Carls young son Mark, born in 1959, Mark was strapped to the bonnet in his carrycot as a baby. His earliest memories of being on the roads to Sheffield and Scunthorpe, later on, if another passenger required his seat then the warm bonnet would again become his perch. At other times, to get into a steelworks with a no children policy, the floor would be the place to hide, better than the steelworks gatehouse with strangers. Whilst dad drove the real thing Mark sat the other side of the cab changing up and down the box, anticipating the next gear change from the familiar noise of the Gardner. This imaginary driving was a skill he practised back at the yard on an engine and gearbox complete with gear lever, steering wheel and seat, mounted in its chassis, devoid of cab, a little like the coach chassis seen being delivered to the coach builders today.

Wagons as they were always called, never trucks or worse still lorries, were to be Mark’s overriding passion, piles of scrap were to be climbed on and hidden in but of no real interest to a young lad. The ability to recognise any wagon from behind at a great distance was a much-practised skill, one he continued to practise as a driver himself although it’s made difficult these days by the fact that so many manufacturers seem to share the same cab! The distinctive shape of the rear axle or even the rear cross member gave the Foden’s away every time. His first visit to Foden’s, Elworth works in 1962 is still remembered, a very nice man struck up a conversation with the three year old and gave him a Foden brochure full of pictures of all the models of the day, a brochure he still today.

During its half a million miles the Foden was only towed home once, and that after an accident. Carl always insists that no load was too big, no hill too steep. On one occasion on a foundry tip, a separating plant used to screen metal from sand was loaded onto a tank transporter weighing 40 tonnes. The Foden, weighing 24 tonnes, pulled itself and the trailer up a slope off the tip. With only 112bhp, low gearing was the Foden’s secret weapon, many like her were used to tow heavy abnormal loads around the country, albeit slowly.

The twelve hours round trip to the North East in a cab that was hotter than a desert in summer and desperately cold in winter, coupled with plenty of handball loading and unloading, inevitably took its toll on the driver. Staying awake could be a problem, with the window down for fresh air, the bonnet side would be unclipped to let even more noise into the already noisy cab, in the mistaken belief that it would help stop a weary driver from nodding off. Singing was another way to stay awake, the Gardner played a universal tune to sing (if that’s the right word) to, Carl at one side murdering a Joseph Locke song, Mark at the other singing something completely different, neither able to hear the other. Conversation across the bonnet was difficult to say the least, Mark found that the best method was to sit on the bonnet next to dads left ear. The shouting though was hard on the voice, and toward the end of the day no one could be bothered to make the effort, a silent journey home, bar for the Gardner hammering away reliably and relentlessly homeward, Marks head against the windscreen watching the road disappearing hypnotically under the big Foden’s wheels.

It was on the visit to Foden’s with RKU that another wagon was spotted, a 14-ton GVW ex Shipstone Brewery Foden FG with a Gardner 4LW and flat body. Enquiries were made and the wagon purchased. Drop sideboards were added to the flat but no tipper for this one. The smaller Schofield vehicles were often used for a variety of haulage jobs, including bagged coke delivery. At this stage scrap was still being delivered to the railway goods yard in nearby Meltham, where the scrap had to be thrown from the road vehicle into the railway truck. Only the smaller wagons could get into a suitable position close enough to the railway truck. The scrap then made the rest of the journey to the steelworks by rail. It is thought that this ceased around 1965. The ‘Little Foden’ as it was always called was eventually parked up in the late 60s and slowly buried with scrap metal. Later, maybe around 1990 it was uncovered and given to mechanics at a Holmfirth mill to renovate at Holmfirth. After a change of oil and battery the 4LW cranked into life with no trouble and after 20 years under hundreds of tonnes of steel. Drawings for the cab were located but changes at the mill meant the project was abandoned. The vehicle then passed for safe keeping to Edward Sykes at Meltham although ownership remained with Schofield’s. After a long time sat derelict on the edge of the moors it was recovered and is currently in pieces at Schofield’s Greenhead yard-minus the engine as Edward refuses to hand it over.

The journey back from Staveley near Chesterfield often meant an afternoon rush hour journey back through Sheffield. This meant trams, get stuck behind a tram and you could be as Carl would say ‘Be stuck behind the bloody thing for an hour’, so an alternative route home was devised. A scenic one. Heading up to Hathersage and Bamford to Ladybower the 8 wheeler then wound its way up hill and down dale across the Strines to Langsett back onto the road home. Norman at this point, not particularly impressed was informed by the errant son that the journey took no longer than Sheffield at rush hour and that the view was far superior, so, father went along for the ride! Well as anyone who has ridden through the peaks, or indeed any place of natural beauty in a wagon will tell you, the higher the view point the better the view. Being able to see over the walls Norman was seeing things never before seen in a lifetime of car journeys. For once father and son saw eye to eye, not a regular occurrence! Usually a journey with either of his sons in wagon would have Norman flinching away from the nearside window, the flinching coinciding with the passing of lampposts or telegraph poles, much to the amusement of whoever was driving.

In 1965 another Foden, this time a 20-ton six wheeler with the S.21 fibreglass cab, not the first fibreglass cab on the fleet as ERF KV 16 tonners had been acquired by now. This Foden, 892 CWW was bought new by Robert Hanson in 1962 or thereabouts, the aluminium coal body was retained initially and she went to work alongside the old 8-wheeler on the Skinningrove run. Gardner’s 6LW was again the engine of choice but the big difference was the Foden 12 speed gearbox, with a 4 speed main box and 3 speed epicyclic unit at the back of it. Ratios were extremely close, driving it was a little like playing the piano. The changes made in the main box with gear lever and range changes made with a short air shift lever on the right-hand side of the steering column. The ratios though, didn’t follow the logical 4 over 4 pattern and care had to be taken with the choice of driver. A simple twitch of the little auxiliary change lever from direct to low range could be enough to split the aluminium gearbox case. The 12-speed box was highly thought of at Schofield’s, a pleasure for the skilled driver to use. When climbing hills loaded the driver could preselect his next change and a quick dip of the clutch, or even a blip of the accelerator, would give a smooth and lightning fast change. Not fool proof but better than the Eaton 2 speed axle, which, if hurried, would leave you stranded without drive, the rear axle growling loudly and then engaging with a very unhealthy bang, by which time forward motion had ceased and a restart would be required. The speed of the change and close ratios were well suited to the daily duelling with any other loaded vehicle that happened to be around and in the way on a suitable stretch of uphill gradient, some victims being chosen on a regular basis. Buses pulling out of bus stops with total disregard for whatever was bearing down on them from behind, could be assured of problems if it was Carl at the wheel. The offside mirror of the bus usually being the price to pay, neatly removed by the nearside rear sideboard pin of the Foden, precision driving no less!

1967 was to see the arrival of the first brand new Foden, OYG 258E, a 22 ton 6 wheel double drive chassis with S21 cab, Gardner 6LX 150, Foden 12 speed gearbox and Foden’s own rear bogie was fitted with a drop side tipper body similar to RKU 535. In fact, OYG and 892 CWU were almost identical at first glance. The newer wagon however had a wider track, so the cab had correspondingly wider wings to cover the wheels. Almost every component worth mentioning on the Foden’s of this era was manufactured in house, they even had their own foundry, this coupled to the low volumes involved was quite probably one of the reasons for their near demise in the early seventies. OYG, as the vehicle was usually referred to or Queen Mary by some, was again supplied by Stanley Hughes, who allowed Schofield’s to take the vehicle and ‘pay for it when you’ve got some brass’, which they did.

Mark remembers the trip to Hughes garage at Cleckheaton to look at the new Foden and being invited upstairs into a room with a bar and billiards table, where Stanley entertained on a Sunday morning. Lapel badges belonging to, now, long defunct manufacturers were thrust into his hand and are still part of a collection amassed by writing to every manufacturer worldwide that he could find the address for, letters, posted 30 at a time, all with the same hand-written letter inside. A response from Japan or Canada could take six months but would be met with great excitement. The envelope battered by its journey would hopefully contain more badges, stickers and glossy brochures, all of which he still has, no e-mail or websites then.

Not long after OYG was acquired it was upgraded to 24 tonnes or 24390 Kg in metric tonnage. The wagon was put straight to work on the Skinningrove run, 892CWW had been converted from tipper to skip wagon by now. Later work was to be a lot more varied with muck shifting and some demolition work undertaken, scrap deliveries usually within an eighty mile radius of home. The new wagon resplendent in its shiny, and by now familiar, maroon and post office red, was a dream come true for Carl, although driving it was shared with Harold Brown, a long-time employee famed for his thirst (for beer), Carl’s time was mostly spent running the yard and crane driving, another passion. Maroon by the way was chosen back in those pre 2nd world war days, because it was Norman Schofield’s favourite colour, many of his cars were also maroon, the post office red chassis complimenting it nicely.

The paint on the cab was, unusually, Cellulose, more commonly used on cars, it gave a high gloss finish that could be polished up for years with no corrosion problems on the GRP cabs, the chassis would be resprayed 2 or 3 times over the years, the cab paintwork was good for 10 years.

In the mid-1970s Schofield’s had diverted into local authority work for the highways department of the newly formed Kirklees Council, virtually every wagon on the fleet was adapted to grit and carry a snowplough, the Foden 6 wheelers however ploughed only, loaded up with ballast it took very deep snow to stop them in their tracks. The arrival of purpose built 6 wheel drive Atkinsons in the late 1970s cut down their ploughing duties though.

The Telehoist skip unit fitted to 892 CWW in 1971 meant the Foden was busy every day collecting and delivering loads of scrap and stone, usually within 50 miles of home, the mileage was mounting, wagons from Robert Hanson’s were no stranger to high mileage and Schofield’s had been clocking the miles up since 1965. The decision was taken to replace the 6LW, still going strong, with a 6LX 150bhp engine. With 30hp more the Foden gained a new lease of life, although life on the motorways wasn’t much fun for driver Roger Brook, away from the motorways, the 150 and 12 speed combination running at 20 tonnes was quite acceptable, outright top speed wasn’t a strong point though, being even lower geared than OYG.

The durability of the Fodens, the reliability of the Gardners, not to mention their economy, the seemingly unbreakable nature of the 12′ chassis, the corrosion proof cab, all these things combined gave Schofield’s and of course many others their ideal wagon, a symbol of British engineering from the 60s at its best. 892CWW ‘retired’ around 1981, it still sits under a pile of scrap in Schofield’s yard, just visible. Mark passed his HGV class one 2 weeks after his 21st birthday in 1980, so had the pleasure of driving it for a while, replaced by a Bedford that would top 70mph, but was gutless on the hills, the old Foden was missed. OYG became Marks next wagon, by now a Gardner 6LXB 180 and welded alloy tipper body had been fitted, a selection of drivers who couldn’t handle the Foden 12 speed had been and gone leaving a trail of damage behind them. A tachograph was fitted, larger convex mirrors in place of the small flat glass, typical of their era, rearward visibility had never been better, a real bonus considering that the tarmacked roads between Schofield’s mountains of scrap were only inches wider than the wagon. Reversing wagons down the yard was a skilled job but occasionally the polished chrome bumper would be bent on some unseen piece of scrap, Oh! For the kerbside mirrors of today. The more substantial steel channel iron fitted along with the snowplough frames solved this problem.

Mark remembers his apprenticeship on OYG with great pleasure, glad that he had the chance to drive it, the Foden air operated windscreen wipers weren’t a favourite feature, heavy snow would stop them, extreme cold would freeze them, strong winds lift them off the extremely curved windscreen of the ‘Mickey Mouse’ cab. A typical day would be a load of cast iron to G.E.Cs Dick Lane foundry at Bradford, tip at 7.00am an empty dash to Staveley, hand load 15 tonnes of S.G Iron into a loading shovel bucket to be tipped into the tipper body, back to Huddersfield, another trip to Dick Lane in the afternoon, if the foundry was busy two loads would be taken, every load taking an hour to place on the wagon with the electro-magnet, 6.00am to 6.00pm being the norm no matter how dark or how rough the weather, the wagons were loaded or ‘set up’ for an early start. Marks real problem with OYG was the 48mph top speed, for a lad wanting to get on, being passed all day on the motorway was extremely frustrating, hills were a different matter, even in the early 80s the Gardner 180 and Foden 12 speed took some beating, things were soon to change though, but more of that later.

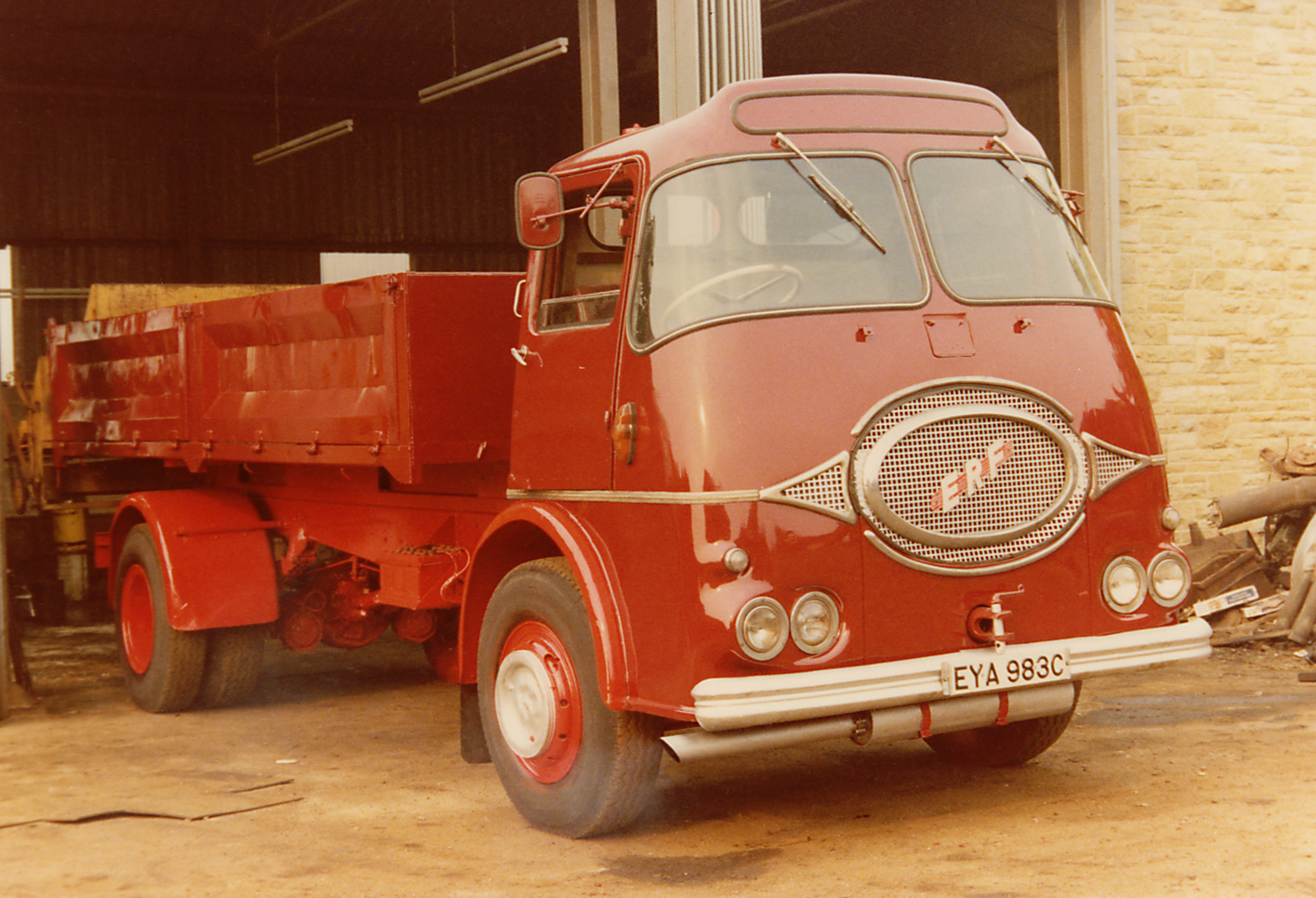

The other mark of note on the fleet was of course ERF, KVs, LVs, B series and E series, all 16 tonners found their way into the Schofield ranks, tippers and skip wagons. Vehicles from Rowntree Mackintosh, Showering’s and Tolman car transporters were bought, many more were used as gritters. EYA 983C was an ex SVW distribution motor, based at Magdale Vinery near Meltham, a 16 tonner fitted with a tipper, had joy of joys a Gardner 6LW 120bhp, not the usual 5LW 100, a David Brown six speed and Eaton two speed axle completed the driveline, standard ERF kit for decades, this particular Browns box had a different, illogical layout to normal, one change being forward into neutral, across the gate and back into the next gear, a fairly large ratio jump made this change quite difficult. The gear lever originating from the rear of the cab between seat and bonnet, not straight up from the floor by the left foot, the changes were short and sweet for a Browns box, better than some cars according to ‘Brooky’. EYA lasted into the 80s, running in tandem with OYG to Fleetwood with steel swarf for export on occasion. Gardner 6LXB 180bhps were to power the later ERFs, drawbar units, six wheelers with an axle removed, tractor units plated at 32 tons, all became 16 tonners on the Schofield fleet, more still as gritters, 6LXCT 230bhp C series making their mark gritting.

One other vehicle bought in 1972 worthy of a mention was a 6×6 AEC militant with a Jones KL10-6 10-ton crane mounted on the back, bought at auction at Ruddington and used primarily in the scrapyard with a magnet fitted. The crane jib overhanging the front meant that a second man had to be carried on the road, this usually meant a day off school for Mark, with its driven front axle, the steering lock was terrible, the AEC 11 litre engine, prone to head gasket problems, after a few years of occasional road trips the AEC was kept taxed but rarely left the yard, in fact it spent most of its life with a 40 foot jib and magnet fitted being driven by Stuart ‘Joe’ Moore, brush painted in yet more Khaki green by Carl, Joe polished the AEC with an oily rag daily. The AEC was cut up and scrapped in the mid-90s after over 20 years of 9 hour days.

Traditionally scrap would be transported around the yard using one of the ‘retired’ 16 tonners, however the need to buy a dump truck for site work in Bradford led to two Foden 6-wheeler dumpers making an appearance. One of these, newer than the other, had Foden’s own two stroke engine, the only one ever bought by Schofield’s. The sound from this engine was distinctive to say the least, during the 60s the Foden 8 wheeler coal wagons with the two stroke engine would be heard high up on the hill at Schofields, as they made their way up the A62 trunk road in the valley bottom toward the climb over Standedge. This vehicle was sent to Bradford and worked hard hauling foundry sand and slag from the Schofield separating and screening plants, abused all the time, occasionally reversed over the edge of the tip by Robert Bulmer, from where it would take the Smith 26 crawler crane rigged as a dragline, Case 1150 crawler shovel and the Foden OYG 258E to extricate it. Robert’s chosen method of loading the dumper seemed to be to bury it and then accelerate through the 12 speed box with its direct low and super low ranges as fast as possible. Other than broken springs the Foden was indestructible.

The other dumper would have appeared to have been built in the 50s, rusty from end to end and fitted with a Gardner 6LW, this one was the yard runabout, no 12 speed for this one, a broken engine mount would cause the engine to hit you on the left leg when reverse gear was engaged and the clutch released. The heavy duty dump truck body was the key to survival in the yard, the heavy cast iron that Schofields bought in to break for the foundries could weigh up to 20 tons and soon wrecked the old road wagons. This Foden dumper sits in front of 892 CWW, buried under scrap but clearly visible to this day. A newer 35 ton 6 wheeler was bought for the site work, fitted with a Cummins engine, 12 speed gearbox and Foden axles this model had twin wheels rather than the super singles of the older models, sold when the site work ceased, deemed too big for the yard. In 1977 possibly, a 25 ton 4 wheeler with Leyland engine and the usual Foden driveline was bought for the yard, short but wide, the vehicle looked almost square. After 10 years with Tilcon though the original body was destroyed, Tilcon included a spare body that had only carried smaller quarry material that was very tidy. For the first time a dump truck was repainted, Carl brush painted the body, Mark sprayed the rest, sign written, she looked very smart. This dumper is still in everyday use carrying scrap up and down the yard-and hasn’t been painted since! On regular occasions artics would attempt to climb one of the steep hills, the 1 in 7 double bend on Linfit Lane usually, leading to Schofields yard, this wasn’t to be advised. With the rear of the trailer dug in to the nearside wall and banking, the tractor unit drive axle resting against the wall at the other side, traction having been lost completely, the 32 ton rig would be helpless. The Foden dumper would be ballasted with 10 or 15 tons of heavy cast, reversed the half mile down the road, a suitably strong wire tow rope connected and away we went, with the artic driver under strict instructions to do nothing but steer, the Foden gearing being so low that to attempt to drive the highly geared artic would have led to much bouncing and snatching and either a broken tow rope or half shaft.

December 1982 saw the first brand new Foden for 15 years. Pelican Engineering at Rothwell had a 30 ton 8 wheeler for immediate delivery, a cancelled order. Already fitted with a bulk coal body it was taken to Bradford to see if it would fit around the foundry’s tight corners. It did. The wagon was fine, the body not so good. A special alloy tipper was to be built with four-foot sides, reinforced floor,1/2′ plywood liner covered in steel, the sides double skinned with replaceable aluminium wear sheets. NMI at Barnsley would build this body, and all future Schofield bodies, owned by Robert Hanson, NMI carried out all the body repairs in the future as well. BYG167Y was delivered at Christmas, ready for the New Year. No Gardner for this one, a Rolls Royce 290L coupled to a Fuller 11609B 9 speed box and Rockwell rear axles. Marks ideal wagon would have had a Gardner 6LXCT 230, however most 30 tonners at that time had either a Cummins 250 or Rolls 265 so the 290 put him ahead of the game. With a top speed close to 80mph and power to spare nothing could touch it, not many artics had 290 horse never mind 8 wheelers. The Foden, with wife to be Anne’s name on the front, set to work with a vengeance, faster journey times and the 18.5 ton payload meant that deliveries were revolutionised, larger cranes and magnets were bought to speed up the loading, deliveries and collections further afield undertaken, working coast to coast, and as far south as Birmingham.

The comfort of the carpeted S10 cab, contrasting dramatically with the bare metal of the S21, its stereo, heated everything, wipers that worked, but most of all, the power, meant that Mark was having the time of his life. The hours were long, up at 4.50am most days, always home for the night and usually dinner, if you were going further afield then you start earlier and would still be back for dinner.

The 180 mile round trip to Fleetwood could be dispatched three times in a day, if needed, but what a day, 540 miles. The trip to Fleetwood could sometimes mean a race with R.J (Bob) Normans bonneted Mack’s from Barnsley, there was one forward control as well, a little faster than the others, bright orange and elaborately coach painted the Mack’s would fly, but they couldn’t catch the Foden uphill or down. Saturday morning would mean a drive along the sea front at Blackpool for a change, with Anne along for the ride.

Marriage and then twelve months later a baby daughter, Leigh, saw a baby seat bolted to the bonnet and history repeat itself, as every day when possible Mark called home to collect Leigh, home being just outside the yard. Leigh went everywhere, sharing lunch or a pint of milk and a piece of currant pasty for an afternoon snack, disposable nappies stored behind the seat. Friends were made everywhere she went, disappearing into scrapyard offices as soon as she arrived.

Although the Rolls Royce behaved itself…. more or less, Schofields were never really comfortable with it, sounding rather like a box of nuts and bolts being shaken, it didn’t instil confidence in its longevity, fortunately across at Patricroft L. Gardner had been busy. New engines had been developed including a 270bhp 6LXDT, looking very similar to the old Gardner’s there were high hopes from die hard Gardner users. The engine that caught Marks eye though was the 6LYT 320bhp at nearly 16 litres, it was a massive, indeed awesome, engine to look at. With the help of Chris Draycott, the Pelican Engineering sales rep, Mark set about persuading dad and uncle George that this was the engine they needed. This vehicle though was to be no cancelled order, built someone else’s spec.

B52SUM, delivered in May 1985, was built exactly as Mark wanted it, alloy fuel tank, air horns, air suspended seat (heated as well) everything a driver could ask for. The driveline remained the same but with the addition of cross axle dif locks as well as the 3rd dif lock. The Foden 12′ chassis had been dropped in favour of a flitched high tensile 10′ channel, the width of the chassis was narrower as well, with Kenworth made aluminium cross members, even alloy spring hangers, Foden rubber suspension, although not helping traction when empty or in the mud, was again chosen, extremely reliable, it had withstood any amount of weight on the previous wagon, so no need to change. The cab was a vast improvement, no carpet this time, brown rubber with tan trimmings, much easier to clean, but still retaining the comfort. In went the baby seat, seat covers and cushions, home from home for the soon to be enlarged family. Huddersfield was to be a hot spot for 8 wheelers with Gardner 6LYTs, Schofields, Geoff Knight at Cumberworth and Rodney Howe at Marsden all ordering within weeks of each other, mention was made in Motor Transport magazine at the time. Another new body from NMI with modifications where needed, the wagon was a beauty.

With the best part of 1000 lb ft of torque at 800 rpm, the big Gardner’s pulling power was a dream, compare it to the Caterpillar 350bhp with 550lb ft at the same revs and there was no comparison, so as the continental competition moved up to 290bhp the Foden kept Schofields ahead of the pack. Again, top speed was 80mph, from the drivers point of view it couldn’t get much better, from the owners point of view though things were different, fuel consumption was low, oil consumption though was a different matter, 1/2 gallon a day, a gallon a day for high mileage 38 tonners, head gaskets and indeed head bolts were prone to failure, the oil and fuel leakage common to the old Gardner’s with their metal to metal build and lack of gaskets, a thing of the past supposedly, was once again a problem. For Schofields a trip to Gardner’s at around three months old sorted the cylinder head problem for good, it nearly finished it off though, on collecting the wagon, Mark thought it prudent to check the oil, it was two gallons short, on the way back through Manchester, an oily rag shoved behind the exhaust manifold by a Gardner fitter, burst into flames but fortunately dropped into the road harmlessly. The other problems remained, an annoyance, but not a major issue.

The speed with which deliveries could be completed was a constant source of irritation, surprisingly, for Carl. Having just nodded off in the kitchen easy chair with the newspaper across his chest and the radio on, the World at One presenter talking to himself, hoping for 40 winks after lunch, Mark would breeze into the room demanding to be loaded. This usually meant that it was time for the daily row. “I wish I was loading you for f…..g China, then you’d be gone for a month” Carl would rant. Mark countering with “Drive your own bloody wagon, if you don’t have me loaded by 2.00pm I won’t get tipped in Bradford, pick up in Manchester and be back for 5.00pm then who will be moaning?” During the 80s and early 90s the 8-wheeler could be run like clockwork, a promise to be in Burnley at 3.00pm after a day darting here, there and everywhere, could be kept usually without a problem. One motorway hold up in a month was a bad month, although the deliveries were planned to avoid trouble spots at peak periods.

Tyres. Tyres could be a problem, scrap metal seems to like biting holes in them, whilst the Schofield yard is one of the tidiest around, tarmac roads swept regularly, tracked machines not allowed to damage the road surface, other yards were appalling, mud a foot deep mixed with metal, puddles like boating lakes, roads requiring the Foden’s dif locks to negotiate them, more like a 4×4 driving track. After wearing the set of Michelins out that were fitted at the factory, new Michelins would be fitted on the front with genuine Michelin remix at the rear usually a successful combination, a previous bad experience with spurious remoulds on BYG167Y was still a recent memory. On deciding to part exchange BYG, a long lead time for a new chassis led Pelican Engineering to give a guaranteed part ex price, but asked that the tyres be better than 60% when they took the wagon. A local tyre firm had been pushing George to try their remoulds although Mark wasn’t impressed with the idea, high speed, usually running fully loaded, whilst wearing cheap remoulds, didn’t sound like a successful combination to him, although saying so would no doubt have led to an order to slow down in less than polite terms. The tyres were fitted, they only had to last a month or so. They didn’t manage it. Within days the tread was parting from the carcass, never quite detaching completely, just flopping and flapping in the 70mph breeze. On one journey back from Nottingham Mark limped off the M1 onto the A61 at Barnsley South to find a phone, no mobiles yet. A total of four tyres were shredding, similar tyres were acquired under warranty and refitted, only to repeat the process. A few weeks later the wagons new owner was, apparently unimpressed with BYGs new shoes and demanded a refund from Pelican, He didn’t appreciate his daily tyre pit stop. Schofields forked out an appropriate sum and the matter was settled. So no more cheap remoulds!!

8 wheelers don’t like tyres. It’s a fact. The fronts wear their shoulders out for the fun of it, the rears just wear out all over full stop, another matter of fact being, the higher the power, the heavier the right foot, the faster the 8 wheeler will eat its tyres (and diesel, but the less said about that the better) scrap likes tyres, tyres don’t like scrap, trying to keep the two apart took effort, and seeing as standing around waiting for ATS to turn up, or even worse still, changing flat tyres back at the yard, wasn’t really Mark’s idea of fun. Great care was subsequently taken to keep the tyres inflated. Every morning, regardless of the weather, all the tyres would be given a kick and wheel nuts given a quick looking at, on leaving a site a gloved hand would be run around every tyre and the twins would be checked for trapped bricks etc, A practice that drew comment, not always positive, surprisingly, but that paid dividend many times over the years. One yard in Nottingham was a nightmare, four punctures in one visit being the record, the thought of having four tyres repaired in Nottingham’s branch of ATS didn’t seem a good idea so B52 SUM was limped home up the M1 at 40mph with four tyres quietly hissing their contempt of scrap metal. Considerable will power was required to keep the big Foden at 40mph, the thought of large bangs and the loss of a rear mudguard or two, never mind the rest of the day spent on the hard shoulder was enough to do the trick. When the coal hauling MAN 290’s sped past though, with their bemused drivers giving a questioning sideward glance at the normally flying Foden, it occurred to Mark that it must take less willpower to quit smoking. The MANs were fast but usually became dots in the Foden’s rear view mirrors, usually running three or four together all sorts of blocking tactics were used by the MAN drivers to stop the Foden passing, patience and power usually won the day though. Schofields two mechanics weren’t particularly impressed at the successful arrival of the 8-wheeler with four tyres to change in a rapid pitstop to enable the Foden to make up for lost time in the afternoon. The gamble had paid off this time.

On another occasion, a particularly high speed, and fully loaded, journey from Qualcast at Derby to a foundry at Brighouse ended in a minor disaster. An attempt to get to Brighouse before the crane driver went for his lunch, which would mean a long wait to unload, had led Mark to push the pedal particularly hard to the metal. The day was a beauty, sunny and hot, whether the tyre was punctured or just damaged we will never know but the bang was loud, the rear offside, outside tyre disintegrated in a massive explosion of dust and rubber shrapnel, Marks heart pounded, looking in the rear view mirror, there was just a massive cloud of brown dust, the rear mudguard protruding at a strange angle, surely there must be damaged vehicles behind, but no, the M62 was remarkably devoid of vehicles that day. As Mark coasted onto the hard shoulder a small van appeared out of the dust and rubber, pulled in behind the limping Foden, by now inspecting the damage to his rear lights and mudguard, Mark was approached by the van driver, expecting abuse, or at the very least a list of damage to the van. He was more than a little surprised to be asked if he was alright by a middle-aged lady. ‘No, no damage to the van’ she said ‘but am I going the right way to Bristol?’. This being the west bound carriageway of the M62 between Leeds and Cleckheaton she was pointed in the direction of the M6, so more or less the right direction, and she drove away happy, albeit with 350 miles to drive. She could however just as easily have gone the other way and headed south on the much closer M1. Needless to say, the Foden didn’t make Brighouse, a mere six or seven miles away, before the crane drivers dinner break.

At around 12 months old the Gardner 6LYT fuel pump developed a fault, this new generation of Gardner engine was fitted with a bought in injector pump, not the tried and tested Gardner home grown variety, a visit to Pelican concluded that the pump had worn out prematurely and would have to be replaced, this proved to be a stroke of good fortune as it coincided with Gardner’s decision to release a 350bhp version of the 6LYT, and what’s more, for £270 the injector pump of the 320 could be adjusted and it would be a 350. This wagon just got better. Mark told no one of his unilateral decision, seeing as the wagon was in for a pump exchange, no one need know, not yet anyway. The first day as a Gardner 350 driver was a revelation, muck shifting alongside Schofields 16 ton ERF VRW546S with its Gardner 180, the Foden sped away from the ERF racing through the gears with new found ease, cousin Richard in the ERF puzzled, normally, aside from on the motorway, the ERF would just about keep pace with Foden on an urban muck shift. Not anymore.

Marks family was expanding a baby in 1986, another in 87 (12 months later!) made three, eldest daughter Leigh had her name alongside Anne’s on the front of B52 SUM. The Foden’s S10 cab proved to be ideal, loads of room, easy to clean, baby seats bolted in, almost every day was a family outing, mother coming along in the afternoon, even the mother in law on the odd occasion! Several sizes of disposable nappy were kept behind the seats along with everything one needed to keep the kids’ content over the years. Long waits to tip or load would be used for teaching, reading, counting and writing, during the journey sums would be set so that mental arithmetic could be practised. When left on their own in the cab, dad on the back in the body supervising loading to prevent damage to his pride and joy, anarchy would reign, war between the siblings usually breaking out, dad banging his fist on the roof and threatening to get in and sort them out. All in all though the times in the Foden cab were happy ones, a stop at the sandwich shop meant a carrier bag full of assorted sandwiches, crisps, cakes and pop for a lunchtime picnic, preferably outside, weather and location permitting, kids and crisps equals crumbs equals mess so eating in the cab wasn’t encouraged, just tolerated!

The 350 6LYT powered Foden was, from the drivers point of view, certainly in terms of 8 wheelers, just about as good as it got, whether it be storming up the local hills or cruising along the northern motorways, this wagon excelled, however doubts were being cast, rumours were circulating of problems with the 6LYT, the afore mentioned head problems, oil consumption, oil and diesel leakage were bad enough but the odd tale of catastrophic failure were extremely worrying. Schofields business couldn’t risk downtime running into weeks so yet again after three years a call was made to Pelican asking a rep to call, spec sheets were examined, torque curves studied and a decision made, Caterpillar. The 10 litre Cat was making a name for itself in Foden 8 wheelers, its mere 300bhp though looked a little underwhelming. The 14 litre 3406 was a different proposition with 350bhp and 1320lb torque this was a beast, a monster weighing hundreds of kilos more the big 16 litre Gardner 6LYT. Built entirely from cast iron not iron and aluminium like the Gardner, its lack of bottom end torque would have to be tolerated, surely an engine with the Caterpillar name would be reliable. Time would tell a different story.

The 350 6LYT powered Foden was, from the drivers point of view, certainly in terms of 8 wheelers, just about as good as it got, whether it be storming up the local hills or cruising along the northern motorways, this wagon excelled, however doubts were being cast, rumours were circulating of problems with the 6LYT, the afore mentioned head problems, oil consumption, oil and diesel leakage were bad enough but the odd tale of catastrophic failure were extremely worrying. Schofields business couldn’t risk downtime running into weeks so yet again after three years a call was made to Pelican asking a rep to call, spec sheets were examined, torque curves studied and a decision made, Caterpillar. The 10 litre Cat was making a name for itself in Foden 8 wheelers, its mere 300bhp though looked a little underwhelming. The 14 litre 3406 was a different proposition with 350bhp and 1320lb torque this was a beast, a monster weighing hundreds of kilos more the big 16 litre Gardner 6LYT. Built entirely from cast iron not iron and aluminium like the Gardner, its lack of bottom end torque would have to be tolerated, surely an engine with the Caterpillar name would be reliable. Time would tell a different story.

E649 OWT set to work in April 1989, improvements to the spec had been made, the relatively trouble free driveline was retained, Fuller 14609B constant mesh box with Eaton rear axles, Foden’s own rubber suspension, the NMI body further modified and improved, the biggest improvement being the paint job on the body, self-etch primer, primer and Masons polyurethane aluminium gloss were applied expertly by NMI, no more rubbing at the bare aluminium with steel wool trying vainly to remove road salt corrosion. The S10 cab restyled once more, rounded now, sitting high above the big CAT, the styling a little bland though, a sun visor, airhorns and upright chrome exhaust stack livened things up a little. The interior though was yet another step in the right direction, not luxurious but practical and comfortable, easy to clean and of course lots of room.

There were several things about this vehicle that really stood out, from the driving seat that is. Power or specifically torque in abundance, at high revs, dismal at low revs, a hill taken at momentum could be flown up with unbelievable ease, however, stop on that same hill of 1 in 5 or 1 in 4 and try to restart, crawler, a gear never before needed would have to be engaged, no chance of a safe up change from scratch, so when less steep ground was reached, first would be engaged and many more revs than was ever needed on any Gardner would be applied, the Gardner 6LYT was almost unstoppable (although typical of earlier Gardner’s it would at near stalling point, flick backwards and proceed to run backwards until the stop was pulled) with luck the CAT powered Foden would pull away. Smoke was the next obvious point, black smoke in abundance when flooring the accelerator, this smoke became a trade mark of all the Cat engines of that era, the 14 litre 3406 didn’t have an exhaust pipe, it had a chimney and smoked like a stream train, thankfully though, only under certain conditions, as the accelerator was applied the engine smoked but would then clear, however, if the driver kept reapplying power, for instance on a flat road or stretch of motorway, then smoke signals could be sent to the next county, much to the amusement of this driver. There was a drawback though, stealth was no longer an option in the daily duel with the other HGVs, the tell-tale black smoke was a giveaway that power was being applied and the speed cranked up, usually on the approach to an uphill incline. So common was the smoke problem with the CAT engines that even the vehicle examiners at the testing station would accept the problem and give the engine a fighting chance during the smoke emissions test by sensible use of the accelerator.

The early morning 170 mile round trip to a foundry in Loughborough was despatched in similar style to the previous Foden- quickly! During these pre speed limiter days of relatively quiet motorways, certainly at times outside of the rush hour, a driver could comfortably maintain speeds that would seem frightening today, as in most things, common sense and intelligence count for more than regulation. Remove either of the former and the latter won’t solve the problem, tail gating at any speed will more than likely lead to accidents and quite likely a trip in a wooden box, the higher the speed the wider the gap, easy enough to remember. Although matching the journey times of the Gardner 350 the big CAT was nowhere near as satisfying to drive the lack of low-end torque was aggravated by a particularly awkward 14609B Fuller gearbox, this was a higher torque version of the previous vehicles gearbox to cope with 1320lb ft torque of CAT. The gear lever was connected to the gearbox by cables, not just any cables but cables developed for use on aircraft, introduced to the Foden chassis during the Americanisation that followed the Paccar take over along with much use of aluminium in cross members and spring hangers etc. but more of that later, these cables had given no problems on B52 SUM but on this vehicle seemed badly affected by the cold, on a frosty morning the gear lever could need a two handed change, hardly the best way of timing a clean change on a constant mesh box, even when warm the gearbox itself wasn’t the easiest, a delay in the revs falling away when the accelerator was released aggravated the problem further. I suffered from very painful repetitive strain injury in my left elbow and had to kick up a fuss at Pelican Engineering, the vehicle supplier, to make them change the cables under warranty. They repeatedly attempted to lubricate the cables which worked initially, but then, as the lubricant congealed and when it was cold, it made things even worse.

Under the umbrella of another Schofield family business, W. Oldcorn Ltd, plant hire, excavation and muck shifting were undertaken, during the 60s and 70s demolition was also on the agenda, the muck shifting though was the bane of Marks life, it usually meant trips to the tip, all the local tips being built to the same specification, bottomless quagmires, if there was a road it would have been built with the sole intention of wrecking a vehicle, strategically placed rocks or kerb stones semi submerged in the mud. A tipper highly polished and gleaming on a Monday morning would be covered in more mud than a basking hippo by lunch. The Foden’s rubber suspension could trap nearly half a ton of the stuff, and although strong and reliable, wasn’t really very good off road, lacking the articulation of the single steel multileaf spring, the 3rd axle and cross axle dif locks helped but only in a straight line, corners being out of the question with the double drive locked solid. Finding level ground to tip on would be the next problem, the tracked machine driver on the tip not at all worried at the thought of an eight wheeler on its side, in fact the machine usually only made two forays on to the tip a day. Mid-morning and mid-afternoon being the norm, the inside of the site office being the more attractive option, meal breaks seeming to account for 6 out of the 8 hours worked. As a machine operator himself Mark had been hired to work on the council tips and hated every minute of it. Only if stuck vehicles were causing the tip staff inconvenience would the site road be repaired. What didn’t help was the council’s own vehicle drivers, they were prepared to charge across the tip at break neck speed, damage to their vehicle of no consequence to them, and trust me, there was a lot of damage, ask any vehicle supplier to the county’s solid waste department about the breakages due to abuse, all have horror stories to tell. One Foden 8 wheel hook loader driver had a block of wood with two six inch nails embedded in it, when he felt the need for an unscheduled break he put it under a tyre and ran over it, radioed for assistance and went to sleep.

Level ground was a must for the bulk tipper driver, hook loaders not as fussy, they could tolerate a slight lean, the single front end tipping ram would start to resemble a banana if tipping on a slope, heavy scrap would slide out at the top of the second ram, clay would stick in the body until the top of the last ram was extended, teetering frighteningly from side to side refusing to budge, not really a pastime for the nervous or the reckless, yet again common sense and caution were the key words.

Self-levelling was the answer. Whichever side of the wagon was lowest would be reversed partially up the side of another tipped load to level things up if there was no other load then stones would be used, laid in a row and reversed onto, the problem with this is that before driving forward with the tipper up, the load must have more or less discharged, otherwise you are soon the not so proud driver of a horizontal tipper! In summer the dust was as a big a problem as the mud, certainly in respect of keeping the wagon clean. Mark envied drivers whose wagons were clean all the time. Geoff Knight another Huddersfield Foden 8 wheeler operator with a penchant for high power would be spotted heading home mid-afternoon with a gleaming vehicle apparently washed every day even though it probably never saw a tip or a scrapyard, Marks wagon on the other was hand washed once a week when time permitted. The design of the S10 cab didn’t lend itself to keeping clean, the full width cab always dirtier than say a Volvo F7 with narrow cab and wider front wings, mirrors and side windows need attention all the time during wet weather.

J.B. Schofield & Sons Ltd

Greenhead, Linthwaite, Huddersfield, West Yorkshire HD7 5TST: 01484 842766

E: accounts@jbschofieldandsons.co.uk